As industrial robotics becomes an essential part of manufacturing, the demand for highly customized cable harnesses has risen significantly.

Cable harnesses are the backbone of robotic functionality, linking components and enabling complex tasks that require flexibility, precision, and resilience.

In this post, we’ll explore why customization of cable harnesses is vital for industrial robots and how it helps meet the specific demands of automation.

CBL-YRC061-1 Yaskawa Robot Teach Pendant Cordset Cable

Why Cable Harness Customization is Essential in Robotics

Industrial robots operate in complex environments that demand precision and durability.

Unlike general-purpose wiring, the customized harnesses used in robots must meet stringent requirements, including resistance to wear and tear, flexibility, and efficient data transmission.

Standardized harnesses rarely suffice, as different robots perform diverse functions that necessitate specific types of connections, lengths, and materials.

Customization allows companies to build tailored solutions that match the unique demands of their robotic systems, optimizing performance and longevity.

Key Benefits of Custom Cable Harnesses in Robotics

1. Enhanced Durability and Longevity

Robots often operate continuously, moving repetitively and sometimes enduring harsh environments.

Customized cable harnesses can use materials and designs that withstand these specific conditions, such as high-flex cables for repetitive movements or heat-resistant materials for high-temperature applications. This durability translates to fewer replacements and reduced downtime.

2. Precise Fit and Reduced Bulk

Cable harnesses tailored to the robot’s design ensure a precise fit, minimizing excess wiring.

This approach reduces weight, prevents unnecessary cable strain, and avoids interference with the robot’s movement.

By reducing bulk, custom harnesses enable smoother operations, particularly in applications requiring agility.

3. Improved Signal Integrity and Performance

In robotics, the transfer of power and data must be reliable to ensure optimal performance.

Customizing harnesses allows for the selection of shielding, grounding, and insulation materials that preserve signal integrity, which is particularly crucial in applications requiring high-speed data transfer or sensitive signal transmission.

4. Enhanced Safety Features

Safety is paramount in industrial settings. Custom cable harnesses can be designed with additional shielding or grounding to protect against electrical hazards and minimize risks of accidents.

Such customization ensures that the cable harnesses not only meet the operational needs of the robot but also comply with industry safety standards.

5. Compatibility with Unique Robotics Functions

Each industrial robot performs specific tasks, from welding to packaging to assembly.

Custom harnesses can accommodate specialized connectors , power requirements, and data needs, ensuring seamless compatibility with the robot’s function. This compatibility extends the robot’s range of functions and ensures that it operates optimally within its intended application.

Key Considerations in Custom Cable Harness Design

1. Environment and Application Requirements

Cable harnesses should be designed with the specific environmental conditions in mind, including factors like temperature, humidity, exposure to chemicals, and movement patterns.

For instance, a welding robot may require flame-retardant insulation, while a robot used in cleanrooms may need anti-static properties.

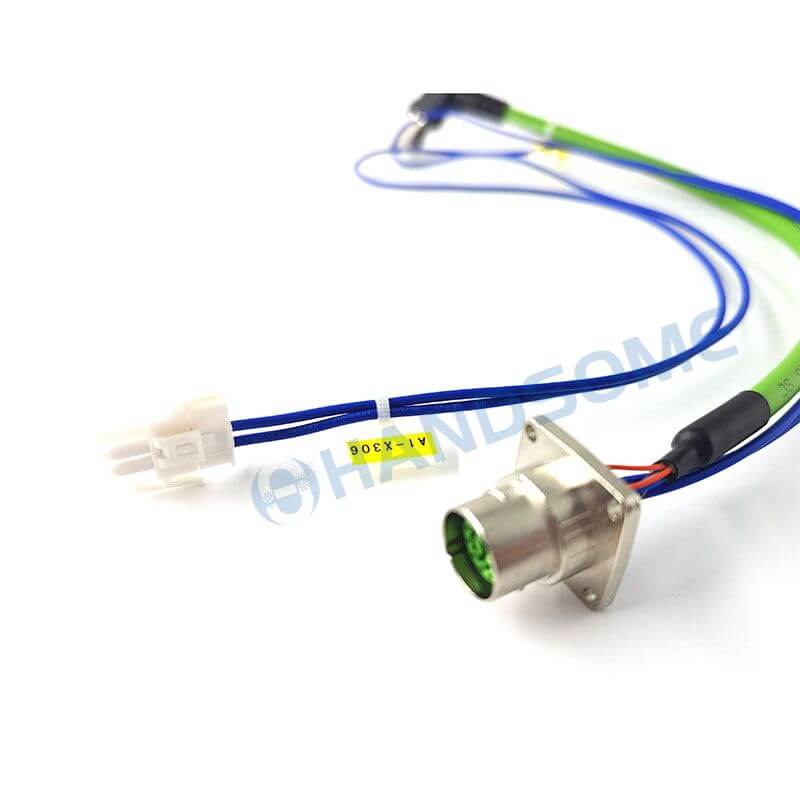

2. Connector and Cable Type Selection

The right connectors and cables are essential for reliable connections.

High-flex cables are suitable for applications involving constant movement, while shielded cables are necessary for noise-sensitive environments.

Proper connector choice is equally critical for ensuring a secure and compatible fit, particularly for complex robotic applications.

3. Flexibility and Bend Radius

Industrial robots perform intricate movements, requiring harnesses with sufficient flexibility to avoid stress and damage over time. Engineers should consider the bend radius and flexibility of cables, especially in areas that experience frequent movement.

Choosing cables with high flex life can significantly improve the longevity of the harness.

4. Future-Proofing for Upgrades

With rapid advancements in robotics, it’s wise to design cable harnesses that allow for future upgrades.

Using modular designs or connectors that support expansion can make it easier to integrate new technologies, ensuring that the cable harness remains functional even as the robot evolves.

HandsomeCable’s Custom Cable Harness Solutions for Industrial Robotics

At HandsomeCable, we specialize in crafting customized cable harnesses designed to meet the exacting needs of industrial robots. Our team understands the importance of flexibility, durability, and precision in robotics, and we work closely with clients to design solutions that align with their operational requirements.

From heavy-duty connectors to high-flex cables, our harnesses are tailored to support complex robotic applications and ensure long-lasting performance.

Our customization process includes:

- Detailed Consultation and Design: Understanding the specific needs of your robots, their tasks, and their operating environments.

- Material Selection and Testing: Selecting cables, connectors, and insulation materials suited to withstand specific environmental and mechanical stresses.

- Prototype and Validation: Testing prototypes to ensure the cable harness meets all required performance and safety standards before full-scale production.

00-170-196 INTERFACE KUKA SMART PAD X19 Robot Cable

Final Thoughts

Custom cable harnesses are integral to the efficiency and reliability of industrial robots. By tailoring harnesses to the unique demands of each robotic application, companies can achieve higher productivity, reduce maintenance costs, and enhance safety standards.

As industries continue to rely on robotics for automation, investing in high-quality, customized cable harnesses will be key to maintaining a competitive edge.

Explore cable in Handsomecable.com to see how we can support your industrial robotics needs. Whether you’re looking to enhance durability, improve precision, or optimize performance, we’re here to help you build the best custom solution for your robots.