Table of Contents

Industrial Robot Cable is an indispensable part of the robot system, which is responsible for transmitting power and data signals among various parts of the robot to ensure that the robot can run normally and perform tasks.

The design and manufacture of cable harness is very important for the performance and reliability of robot, so the selection and maintenance of cable harness for industrial robot need special attention.

The function and application of industrial robot Cable harness

The applications of Industrial Robot Cable mainly include power distribution, data transmission, pipeline system connection and servo motor connection, etc. .

These functions make the cable harness a key element in the proper operation of the robot.

For example, a harness can transfer power from the robot’s control system to an actuator, and data collected by sensors can be transferred back to the control system for processing.

Industrial robot harness plays a vital role in robot system. Its main functions and applications include the following aspects:

Power distribution: the harness is used to transfer power from the robot’s control system to various actuators, such as motors and drives, to ensure that all parts of the robot get the necessary power supply to perform tasks.

Data transmission: the harness is also responsible for transmitting data signals between the robot’s sensors, controllers and actuators. These signals, which may include sensor data, control instructions and state information, are essential for precise control and feedback of robots.

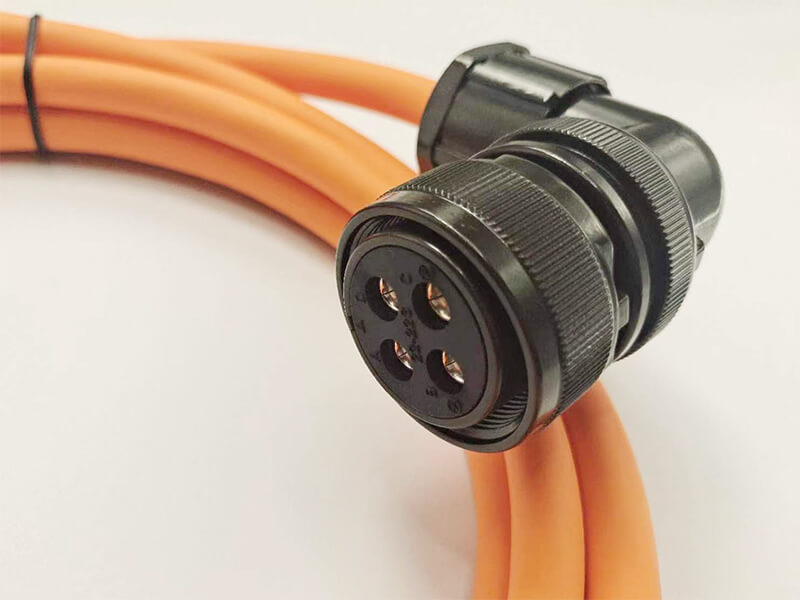

Connecting servomotors: servomotors are one of the key components of the robot. Cable harness is used to connect these motors to the control system to transmit the necessary power and control signals for accurate motion control.

Assembly Line system: in an automated production line, the Cable harness is used to connect various equipment and machines to ensure smooth operation of the entire production process. They may be connected to conveyor belts, assembly machines, and other automation equipment for efficient production operations.

Adapt to complex environment: industrial robot Cable harness usually needs to have good oil resistance, bending resistance, anti-wear performance, to adapt to the complex industrial environment and frequent movement requirements.

Custom Design: in order to meet the specific application requirements, industrial robot Cable harness often needs custom design. This includes harness lengths, specifications, colors, etc. , as well as special connectors and cable types to suit specific working environments and mechanical structures.

Quality and safety: the quality and safety of Cable harness products are very important for the stable operation of robot system. Therefore, Cable harness in the factory before the need to go through strict testing, including on-off, voltage, resistance, insulation and other security tests to ensure its reliability and security.

Through the above functions and applications, the Cable harness of industrial robot ensures the effective operation and efficient production of the robot system, and improves the safety and reliability of the operation

Design requirements of Industrial Robot Cable

When designing Industrial Robot Cable, it is necessary to consider the range of motion of the robot and the number of bending cycles of the cable harness.

The harness needs to be able to withstand up to 150 million bending cycles to ensure that the robot will not fail over long periods of time.

In addition, the cable harness design also needs to take into account the robot’s motion characteristics to ensure that the cable harness will not be over-stretched or distorted during the robot’s movement.

The cable harness design requirements of industrial robots involve many aspects to ensure that the cable harness can work stably and reliably in various working environments. Here are some of the key design requirements:

Electrical performance: Cable harness must meet the robot’s current requirements and voltage levels, select the appropriate wire diameter and material to withstand the expected current load, ensure that the cable has low impedance and high shielding efficiency, to ensure the accuracy and stability of data signal transmission.

Mechanical properties: the cable harness needs to have the characteristics of abrasion resistance, tensile resistance, torsion resistance to adapt to the robot in high-speed movement and complex environment requirements. In addition, the cable harness design should take into account the robot’s range of motion and bending radius, to avoid excessive bending or distortion caused by damage.

Environmental Adaptability: High Temperature, oil, corrosion resistance, flame retardant materials should be selected to adapt to the industrial environment may encounter extreme temperature, chemicals, oil stains and other challenges.

Safety certification: Cable harness should comply with relevant international or national standards, such as UL, CE certification, to ensure electrical safety and fire performance.

Structural design: Cable harness should be Modular design for easy installation and maintenance. Routing path should be reasonable planning, avoid in the joints, rotating parts caused by excessive wear or uneven force. Use special groove or clamp to fix the cable harness to prevent poor contact or damage caused by vibration.

Integrated Management: Through the form of pipeline package or Cable harness, can integrate many wires together, easy to install, management and maintenance, but also keep the appearance of the robot clean, improve production efficiency and safety.

Compatibility and scalability: Harness Design should consider compatibility with other robot components and control systems, supporting flexible configuration and expansion to adapt to different product line layouts and mission requirements.

Standard compliance: wiring and Cable harness design needs to comply with relevant standard requirements, such as wire specifications, connector types, Cable harness protection. The stability of electrical connections and the freedom of movement of the robot should be taken into account in the design of wiring and wiring Android.

By meeting the design requirements, the Cable harness of industrial robot can ensure the high-efficiency, safe and reliable operation of robot system, and also improve the safety and production efficiency.

Fanuc Power Cable F06B-0001-K008

Materials and fabrication of Industrial Robot Cable

To meet the requirements of industrial robots operating in harsh environments, harnesses are usually made of durable materials such as silicone cables, polyurethane cables, and prepreg polyvinyl chloride (PVC) cables.

These materials have good temperature resistance, oil resistance and chemical resistance, to ensure that the harness in a variety of environments can be stable work.

The material and manufacture of industrial robot cable harness is the key factor to ensure the performance and reliability of cable harness.

The following are some of the key considerations for the cable harness material selection and manufacturing process for industrial robots:

Wire selection: wire is usually required to have good electrical conductivity and sufficient mechanical strength. Common wires include bare copper, tinned copper, or aluminum, which provide efficient power and signal transmission.

Insulation Materials: the choice of insulation materials for the safety and durability of Cable harness is very important. Common insulation materials include PVC (polyvinyl chloride) , PUR (polyurethane) and TPE (Thermoplastic elastomer) , which have good heat resistance, oil resistance and chemical resistance. For example, PUR insulation material is suitable for high temperature and oil pollution environment because of its excellent heat resistance and oil resistance.

Shielding material: for Cable harnesses that need to be EMI resistant, shielding materials such as copper braid or aluminum foil layers are used to wrap the cable to reduce external interference and protect signal integrity.

Sheathing material: sheathing material is used to protect internal wires and insulation from physical damage and environmental factors. Common sheathing materials include PVC, Pur, and TPE, which provide varying degrees of abrasion resistance and UV resistance.

Manufacturing Process: the harness manufacturing process including stripping, crimping, injection molding and other technical capabilities, these processes to ensure the quality and performance of the harness. For example, a high-quality crimping process ensures a strong connection between the connector and the wire, reducing contact resistance and potential failure points.

Testing and quality assurance: Cable harness needs to be tested during and after manufacture, including electrical continuity test, high voltage insulation test, to ensure the reliability and safety of Cable harness.

Custom services: many harness manufacturers provide custom services, according to the specific needs of customers to design and manufacture harness, including harness length, specifications, color, etc. .

International standards and certification: Harness products should comply with international manufacturing standards and be certified accordingly, such as ISO 9001:2015, which shows the manufacturer’s commitment to high-quality harness services and products.

Through the above material selection and manufacturing process, industrial robot Cable harness can meet the needs of high-strength industrial applications, and ensure long-term stable and reliable performance.

Fanuc Encoder Cable A660-2005-T506

Customization and testing of industrial robot Cable harness

Because each robot project may have specific harness requirements, harness manufacturers typically provide custom services.

Depending on the precise specifications of the customer, the manufacturer can manufacture harness to meet specific application requirements.

During the production process, each harness is subjected to rigorous testing and inspection to ensure compliance with ISO standards and customer specific requirements.

The customization and testing of industrial robot Cable harness is an important step to ensure that the Cable harness meets the specific application requirements and safety standards. Here are some more details about industrial robot harness customization and testing:

Custom industrial robot Cable harness

Requirements Analysis: first, we need to communicate with customers, understand the robot’s specific application scenarios, working environment, range of motion and electrical requirements, in order to design to meet the needs of Cable harness.

Design Stage: design Cable harness layout, length, specification, color and connector type according to requirement analysis. The maintainability and durability of the cable harness should also be considered in the design.

Material Selection: select suitable wire and insulation materials, such as PUR (polyurethane) sheath material, with oil resistance, bending resistance and anti-wear characteristics, to adapt to harsh industrial environment.

Manufacturing Process: according to the design drawings and material specifications, the cable harness manufacturing, including cutting, stripping, crimping, assembly and molding process steps.

Custom services: provide custom services such as the customization, procurement and assembly of Dresspack components, as well as the manufacture of each wire and cable according to customer specifications.

Testing industrial robot Cable harness

Safety test: the Cable harness must undergo strict safety test before leaving the factory, including on-off test, voltage test, resistance test and insulation test to ensure the reliability and safety of the Cable harness.

Performance Testing: insulation testing of high voltage cables to ensure that they do not break down at high voltages, and electrical continuity testing to ensure that all connections in the harness are correct and secure.

Quality assurance: in the testing process, can provide detailed test reports and data analysis, help users to carry out data analysis, ensure that Cable harness quality in line with ISO standards.

Testing equipment: use professional Cable harness testing equipment, such as ATX-3000S series desktop Cable harness cable tester, it has a self-learning function, can quickly detect the Cable harness cable access, short circuit, open circuit and other connections, and automatically record the test report.

After the test reset: after the test is completed, the equipment should be able to reset automatically to ensure the safety of the test process.

Through customization and testing, the industrial robot Cable harness can meet the specific application requirements and ensure the performance and safety in actual use. It is very important for the stable operation and efficient production of robot system

FAQ: How to carry out the functional test of industrial robot Cable harness?

A functional test of an industrial robot harness usually involves the following steps:

Preparation of test equipment: first, the need to prepare the appropriate harness test equipment, such as harness tester, these equipment can be used for on-off testing, resistance testing, insulation testing, etc. . Ensure that the test equipment meets the test requirements and is in good working condition.

Make test plan: according to the cable harness design and application requirements, make a detailed test plan. This includes determining the cable harness parameters to be tested, such as voltage, current, resistance, and so on.

On-off test: the use of harness tester on the harness on-off test, check the harness of each wire is on, whether there is open or short-circuit phenomenon.

Conduct resistance tests: measure the resistance of the wire in the harness to make sure it is within the specified range. Too High or too low a resistance value may indicate a problem with the cable harness.

Conduct insulation testing: conduct insulation testing on the Cable harness to ensure that the insulation layer of the Cable harness is not damaged to prevent leakage and short circuit.

Voltage withstand test: the harness for voltage test, check whether it can withstand the specified voltage without breakdown, to ensure the safety of the harness.

Record and analyze test results: after the test is completed, record all test data and analyze it. If any non-conforming result is found, the Cable harness needs to be repaired or replaced.

Regular testing and maintenance: in order to ensure the long-term reliability of Cable harness, functional testing should be carried out regularly, and the necessary maintenance and replacement according to the test results.

Through the above steps, we can effectively test the Cable harness of the industrial robot to ensure its performance and safety, thus ensuring the normal operation of the robot system

FAQ: How to select a suitable harness tester for industrial robot harness testing?

Several key factors need to be considered in selecting the appropriate harness tester for industrial robot harness testing:

Test requirements: first, identify the type of harness and test items you need to test, such as on-off test, resistance test, insulation test, withstand test, etc. . Different testing projects need Cable harness tester to have corresponding testing function.

Test accuracy: select the harness tester, to consider whether its test accuracy to meet your requirements. For example, some high-precision harness testers can provide a minimum of 0.002 ohms of test accuracy, which is critical to ensure harness performance.

Test speed and efficiency: industrial robot harness testing usually needs to be fast and efficient, so it is necessary to select a device that can provide rapid test results. Some harness testers have the function of self-learning, which can quickly detect the connection relation of the harness, such as the path, the short circuit, the open circuit and so on, and improve the testing efficiency.

Extensibility and compatibility: Consider the extensibility of the harness tester to ensure that it can accommodate the increased testing requirements in the future. At the same time, the tester should be compatible with different types of Cable harness and connectors.

User interface and ease of operation: choosing a harness tester with a user-friendly interface can simplify the operation process and reduce operational errors. Some devices are equipped with touch screens and intelligent test software, making the test operation more convenient.

Data Management Skills: good data management skills are important for recording and analyzing test results. Select a harness tester that can automatically record test reports and support data export and storage.

Security: Security is an important consideration in industrial testing. To ensure the automatic reset of the Cable harness tester after high voltage testing, and to ensure the safety of the testing process.

Brand and The Adjuster: select well-known brand harness testers are often more reliable product quality and better after-sales service.

By considering the above factors, you can select a suitable harness tester for industrial robot harness testing to ensure the performance and safety of the harness, thus ensuring the normal operation of the robot system and efficient production

Fanuc Brake Cable A06B-6114-K124

Maintenance and service life of industrial robot Cable harness

The maintenance of industrial robot Cable harness is very important for extending the life of robot system.

Reasonable harness management can reduce cable and wire wear, reduce maintenance costs, and improve the reliability of robot system.

In addition, the choice of high-quality Cable harness products and regular maintenance check can effectively extend the life of Cable harness.

FAQ: How long is the maintenance period of industrial robot Cable harness?

The maintenance cycle of industrial robot Cable harness will vary according to the operation cycle, working environment and movement mode of the robot.

In general, if the robot is operating in a highly polluted or harsh motion mode, the harness should be set at a shorter check interval.

For example, some maintenance guidelines may recommend checking timing belts and battery packs every 36 months, but that does not mean that harness maintenance cycles should follow this interval.

In fact, harness maintenance may require more frequent inspection, especially for cables that can move freely and are not hindered by debris such as sand, Ash, and debris.

Therefore, the specific maintenance cycle should be adjusted according to the actual situation and manufacturer’s recommendations to ensure the good condition of Cable harness and reliable operation of the robot.

FAQ: What are the key points to pay attention to in the maintenance of industrial robot Cable harness?

The maintenance of industrial robot Cable harness is an important link to ensure the normal operation and extend the service life of the robot. When performing harness maintenance, the following key points should be noted:

Safety First: before performing any maintenance work, be sure that the robot is completely powered down and that all safety measures are in place to prevent accidental electric shock or mechanical injury.

Regular inspection: according to the robot’s frequency of use and working environment, formulate a reasonable harness inspection cycle. Check Cable harness for signs of wear, cutting or extrusion damage, and replace Cable harness in case of problems.

Cleaning protection: clean Cable harnesses regularly, especially when they are moved, to prevent the accumulation of dust and debris from affecting the flexibility and conductivity of the harnesses. At the same time, ensure that the protective bushing and insulation layer of Cable harness intact.

Correct connection: when connecting or replacing Cable harness, must use the correct Cable harness, and ensure that the connection is firm. Incorrect Cable harness or improper connection may lead to robot failure or safety accident.

Avoid excessive bending: when wiring, should avoid the Cable harness excessive bending or distortion, which may damage the Cable harness internal and lead to failure. At the same time, ensure that the bending radius of the harness to meet the manufacturer’s requirements.

To prevent mechanical damage: the use of pipelines, cable tanks and other protective measures to prevent people or equipment stepped on or rolled cable harness. At the same time, avoid Cable harness and other high-voltage wiring together or parallel arrangement to prevent electromagnetic interference.

Environmental Adaptability: according to the characteristics of the robot working environment, choose the suitable Cable harness materials and types. For example, high-temperature or corrosion-resistant Cable harnesses should be used in high-temperature or corrosive environments.

Record and track: record the maintenance history of the Cable harness, including check dates, found problems, replaced Cable harness, etc. . This helps track the status of the Cable harness and predict future maintenance needs.

Professional Training: ensure that all harness maintenance personnel are properly trained and have relevant safety knowledge and operational skills.

Use original or approved spare parts: when replacing Cable harness, the original or manufacturer approved spare parts should be preferred to ensure the quality and compatibility of Cable harness.

By following the above key points, the Cable harness of industrial robot can be effectively maintained to ensure the stable operation and Operation Safety of robot system.

FAQ:How to judge if the Cable harness of industrial robot needs to be replaced?

Determining whether an industrial robot harness needs to be replaced usually involves the following checks:

Appearance Check: check the Cable harness whether there is obvious wear, rupture, ablation marks or bare wire. If the outer insulation of the Cable harness is cracked or detached, which may lead to a short circuit or an electric shock accident, the Cable harness should be replaced immediately.

Functional Testing: electrical testing of Cable harness, check whether there are open circuit, short circuit or abnormal resistance and so on. The use of professional harness testing and quality assurance equipment, such as harness testers, can ensure the reliability and safety of the connection.

Performance degradation: if the robot performance degradation, such as slow response speed or inaccurate movement, may be due to Cable harness aging or damage caused. Consider replacing the Cable harness after other possible causes have been ruled out.

Bending cycle times: industrial robot cable harness will experience a lot of bending and twisting during long-term use, which may lead to internal wire breakage. According to the manufacturer’s regulations, if the harness reaches or approaches the number of bending cycles of its design, it should be considered for replacement.

Environmental factors: Cable harness may be subject to the working environment temperature, humidity, chemicals and other factors. In case of deterioration or corrosion of the harness material, replace the harness with one suitable for the environment.

Preventive maintenance plan: according to the robot’s frequency of use and working conditions, develop preventive maintenance plan. Check Cable harnesses regularly and replace them as planned to avoid unexpected failure and downtime.

Manufacturer’s recommendations: refer to robot manufacturer’s recommendations and Cable harness replacement guidelines. The manufacturer will usually provide the life expectancy of the harness and a replacement schedule, and following these recommendations will ensure the best performance and safety of the robot.

When replacing harnesses, ensure that harnesses that meet specifications and quality standards are used and are operated by trained professionals to ensure the safety of the replacement process and the reliability of the harnesses

Markets and suppliers of industrial robot harnesses

The market of industrial robot harness is a growing field with the rapid development of industrial automation and intelligent manufacturing. Here are some key pieces of information about the industrial robot harness market:

Market size and growth trends: according to the report, the global market for industrial robot harnesses in the 2023 has reached significant size and is expected to grow significantly by 2030. In the Chinese market, sales of industrial robot harnesses have already reached a certain amount in 2022, and the 2029 is expected to achieve a higher market size with a compound annual growth rate (CAGR) of a certain percentage over that period.

Product type and application: the product type of industrial robot harness mainly includes power cable, signal cable, communication cable, sensor cable and safety cable, etc. . In terms of applications, the automotive industry is one of the major applications of industrial robot harnesses and is expected to maintain a high annual compound growth rate in the coming years.

Region Analysis: the asia-pacific region is an important part of the global industrial robot harness market, especially China and Korea, and is expected to achieve high CAGR in the coming years. In the Chinese market, the development of industrial robot harnesses is strongly supported by national policies, such as the 14th five-year plan for the development of the robot industry, which promotes the expansion of the depth and breadth of robot applications.

Market drivers: the growth of the industrial robot harness market has been driven by a number of factors, these include increased levels of industrial automation, increased manufacturing demand for efficient production, and increased investment in smart manufacturing and unmanned plants.

Challenges and risks: despite the promising market prospects, the industry of robotic harnesses is also facing some challenges and risks, such as the fluctuation of raw material cost, the pressure of technological upgrading, and the intensification of international market competition.

Future outlook: it is expected that the market for industrial robot harnesses will continue to grow as technology advances and applications expand. At the same time, the improvement of localization degree and the optimization of cost control will help to improve market competitiveness.

To sum up, the industrial robot harness market is in a rapid development stage, driven by the trend of automation and intelligence, the market prospects are broad.

At the same time, competition and challenges in the industry also prompt enterprises to innovate and optimize products and services to meet the growing market demand

Handsome Cable focuses on industrial Robot Cables, currently including KUKA Robot Cables, ABB Robot Cables, Yaskawa Robot Cables, FANUC Robot Cables, Epson Robot Cables, Kawasaki Robot Cables, Nachi Robot Cables, Panasonic Robot Cables, Mitsubishi Robot Cables

Handsome continues to evolve to bring high quality, high performance Cable harnesses to the world.

Merci pour cette lecture , see you