Table of Contents

M12 connectors are a popular choice for industrial automation, transportation, and networking applications due to their robustness, reliability, and compatibility with a variety of devices.

As the demand for secure, versatile, and efficient connections grows, understanding the different M12 connector standards and options is crucial for selecting the right one for your application.

This guide will walk you through the key aspects of M12 connectors, from coding types to mounting options, so you can make an informed choice.

Understanding M12 Connectors and Their Versatility

M12 connectors come in a range of styles, each optimized for specific applications.

The “M12” designation refers to the 12mm metric diameter of the threaded locking mechanism, making them compact yet durable solutions for tight spaces.

From M12 panel mount connectors to M12 bulkhead connectors, each version offers unique benefits depending on the installation needs.

1. M12 Panel Mount Connectors

M12 panel mount connectors are designed for secure mounting on control panels or equipment housings, providing a streamlined connection to external cables.

These connectors offer durability in harsh environments and are often used in factory automation, process control, and transportation applications.

When choosing a panel mount connector, it’s essential to verify the coding type and the panel thickness compatibility to ensure secure and reliable installation.

2. M12 Network Connectors

For high-speed data transmission, M12 network connectors are frequently used in Ethernet applications, such as PROFINET and EtherCAT networks.

These connectors support data communication up to 10 Gbps, making them suitable for real-time data exchange in industrial IoT environments.

When selecting an M12 network connector, consider factors like data rate requirements and IP rating, which ensures resistance to dust and water ingress.

Gender and Wiring Options: M12 Male and Female Connectors

M12 connectors are available in both male (plug) and female (socket) formats. Male connectors feature exposed pins, while female connectors have recessed contacts, ensuring a reliable mating connection that reduces the risk of mismatches.

Both types are used across various applications, and they are typically threaded to provide a secure lock during operation.

Another important option is the M12 field wireable connector, which allows for on-site wiring without the need for specialized tools.

This flexibility is especially beneficial in custom installations where pre-molded connectors may not be practical.

M12 Connector Coding

M12 connector coding is a critical feature that helps ensure correct mating and application compatibility.

Each coding type is designed to prevent mismating and is intended for specific applications.

Here’s a brief overview of some common M12 coding types:

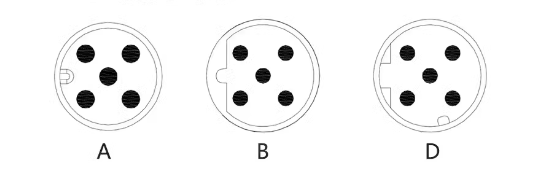

M12 A-coded connectors: The most common coding type, A-coded connectors are typically used for sensor and actuator applications, as well as DC power connections. These connectors usually come in configurations from 3 to 12 pins, making them versatile for many industrial applications.

M12 B-coded connectors: Often used in fieldbus networks such as PROFIBUS, B-coded connectors are optimized for data communication.

M12 D-coded connectors: These connectors are primarily used in Ethernet and Fast Ethernet (up to 100 Mbps) applications, suitable for networking and data transmission.

M12 X-coded connectors: Designed for high-speed data transmission, X-coded connectors support data rates up to 10 Gbps, making them ideal for applications requiring rapid data transfer, like video surveillance and data-intensive automation.

Understanding the coding of M12 coded connectors is essential for ensuring compatibility with your application’s requirements.

Using the wrong coding can lead to connection failures or equipment damage, so always verify the coding before finalizing a connector choice.

M12 Bulkhead Connectors

M12 bulkhead connectors are commonly used for panel penetration and offer a secure and durable interface between devices on opposite sides of an enclosure or wall.

They are ideal for applications requiring sealed, water-resistant connections, such as outdoor installations or environments exposed to dust and moisture.

Selecting an appropriate bulkhead connector involves considering both the coding type and IP rating, as well as panel thickness for a proper fit.

Choosing the Right M12 Connector for Your Application

When selecting an M12 connector, consider the following factors:

- Application requirements: Determine the coding type that fits your application, whether it’s for power, sensor connection, or data transmission.

- Environmental conditions: Ensure the IP rating matches your environment, especially if the connector will be exposed to moisture, dust, or vibration.

- Installation requirements: Decide whether you need a panel mount, bulkhead, or field-wireable connector based on the installation constraints and ease of access.

- Gender and pin configuration: Choose the correct gender (male or female) and pin count to match the device or network specifications.

Final Thoughts

M12 connectors offer unmatched flexibility for various industrial applications, with options suited for everything from secure panel mounting to high-speed data transmission.

By understanding the distinctions between different types of M12 panel mount connectors, M12 network connectors, and various coding options like M12 A-coded connectors, you can select the perfect connector to meet your needs.

Making an informed decision based on your application’s environmental conditions, data requirements, and installation constraints will ensure reliable performance and reduce the risk of connector failure.

Whether you need an M12 male connector or M12 female connector in a specific coding type, choosing the right M12 connector can enhance the efficiency and durability of your industrial systems.

M12 Connectors Related Blog

Understanding the IP Ratings of M12 Connectors for Outdoor Applications

Why Shielded M12 Connectors Matter for Industrial Data Transfer

The Role of M12 Connectors in the Future of IIoT and Smart Factories

How to Choose the Right M12 Connector for Your Industrial Application

A Comprehensive Guide to M12 Connectors: Types, Applications, and Benefits

M12 Connector Standards: What to Know Before Choosing a Connector