Table of Contents

In today’s world of industrial automation, connectivity is key.

Reliable and durable connectors ensure seamless communication, data transfer, and power supply across machines and systems.

Among these, M12 connectors have become a popular choice due to their robust design and adaptability.

This guide will explore everything you need to know about M12 connectors: their types, applications, and the benefits they bring to industrial environments.

What is an M12 Connector?

The M12 connector, named for its metric thread of 12 mm, is a circular connector widely used in industrial settings.

These connectors are often chosen for their reliability, compact size, and resistance to vibration, water, dust, and other environmental stressors.

M12 connectors are commonly seen in applications where secure connections are crucial, including factory automation, robotics, and industrial machinery.

Types of M12 Connectors

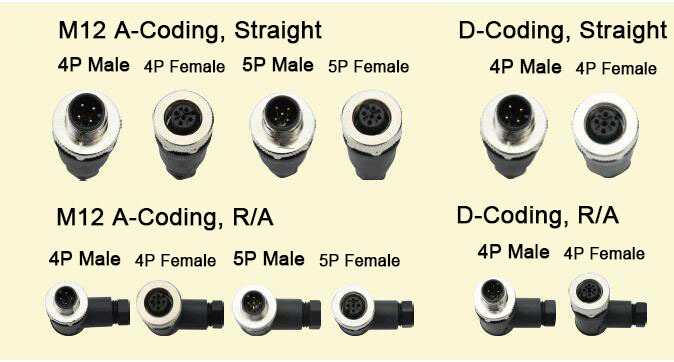

M12 connectors come in several configurations, each designed to meet specific industrial requirements.

The most common types include:

1. A-Coded: Primarily used for sensors and actuators. A-coded M12 connectors support up to four to eight pins and are typically used in applications requiring power or signal transmission.

2. B-Coded: Used for Profibus connections, B-coded M12 connectors are tailored for data transmission applications and are typically employed in industrial Ethernet connections.

3. D-Coded: Often used for Fast Ethernet (100 Mbps) data transmission, D-coded connectors are popular in industrial communication systems, where reliable data transfer is essential.

4. X-Coded: Designed for high-speed data transmission, X-coded M12 connectors support Gigabit Ethernet applications, allowing speeds of up to 10 Gbps. This type is frequently used in applications that require high data bandwidth, such as video monitoring systems and industrial cameras.

Each code indicates the connector’s specific application, offering varied pin arrangements, data rates, and shielding options for different industrial needs.

Applications of M12 Connectors

M12 connectors are versatile and support a wide range of applications across different industries:

Factory Automation: M12 connectors are widely used in factory settings, connecting sensors, actuators, and controllers that manage and monitor production processes.

Industrial Ethernet: With their ability to withstand harsh environments, M12 connectors are perfect for Ethernet applications, providing stable network connections in rugged industrial settings.

Transportation: These connectors are commonly used in automotive and rail industries due to their reliability in high-vibration environments and resistance to water and dust.

Robotics: M12 connectors support the high-speed data transmission necessary for robotics, enabling precise control and feedback for efficient robot operation.

Agricultural Machinery: Given the exposure to outdoor elements, M12 connectors are ideal for connecting sensors and controls in agricultural machinery, ensuring durable performance in unpredictable environments.

Benefits of Using M12 Connectors

M12 connectors offer several key advantages, making them an essential component in modern industrial setups:

1. Durability: With robust construction and resistance to water, dust, and corrosion, M12 connectors maintain functionality in challenging conditions, reducing downtime and maintenance needs.

2. Compact Design: Their small size allows M12 connectors to be used in compact, space-constrained environments without compromising on performance.

3. High Data Transmission Rates: The availability of X-coded connectors enables high-speed data transfer (up to 10 Gbps), which is crucial for applications like video monitoring and fast data communication in industrial networks.

4. Versatile Coding Options: The multiple coding options (A, B, D, X) provide flexibility for various application needs, from simple power connections to high-speed data transfer.

5. Reliable Performance: M12 connectors are engineered to provide secure and consistent connections, even in high-vibration or high-temperature environments, making them ideal for mission-critical applications.

Choosing the Right M12 Connector

When selecting an M12 connector, it’s essential to consider factors such as the type of data transmission needed, environmental conditions, and the required pin configuration.

For example:

- For sensors and power applications, an A-coded connector would be ideal.

- For Profibus and data communication, a B-coded connector would meet the requirements.

- For high-speed Ethernet applications, a D-coded or X-coded connector would provide the necessary data rate and reliability.

A B C D-Coded m12 to rj45 Connector M12 to RJ45 Adapter

Conclusion

M12 connectors are a critical component in industrial automation and data communication systems.

Their robust design, versatile applications, and ability to withstand harsh conditions make them indispensable in various industries.

Whether you need reliable connectivity for sensors, Ethernet communication, or high-speed data transfer, there’s an M12 connector suited for the job.

When choosing an M12 connector, understanding the specific needs of your application can ensure that you select the right type, improving the overall performance and longevity of your industrial systems.

By investing in high-quality M12 connectors, companies can enhance connectivity, reduce maintenance costs, and ensure consistent performance, even in challenging industrial environments.

For more information or assistance in choosing the best M12 connectors for your applications, feel free to explore our product offerings at Handsome M12 Connectors or contact our team for expert guidance.

M12 Connectors Related Blog

Understanding the IP Ratings of M12 Connectors for Outdoor Applications

Why Shielded M12 Connectors Matter for Industrial Data Transfer

The Role of M12 Connectors in the Future of IIoT and Smart Factories

How to Choose the Right M12 Connector for Your Industrial Application

A Comprehensive Guide to M12 Connectors: Types, Applications, and Benefits

M12 Connector Standards: What to Know Before Choosing a Connector