Table of Contents

In industrial automation, where precision, durability, and reliability are paramount, choosing the right connectors is critical.

Whether you’re managing robotic systems, assembling power distribution setups, or maintaining industrial equipment, M16 connectors often emerge as the go-to solution.

But the question remains: where should you buy reliable M16 connectors that meet your exacting standards?

Let me share insights from my years of experience as an engineer and purchaser in the electronic and industrial automation industry.

Along the way, I’ll sprinkle in practical tips, pitfalls to avoid, and a few lessons I’ve learned while sourcing these vital components.

Understanding the Importance of M16 Connectors

Before diving into where to buy them, let’s revisit why M16 connectors are so valuable in industrial applications.

Why M16 Connectors?

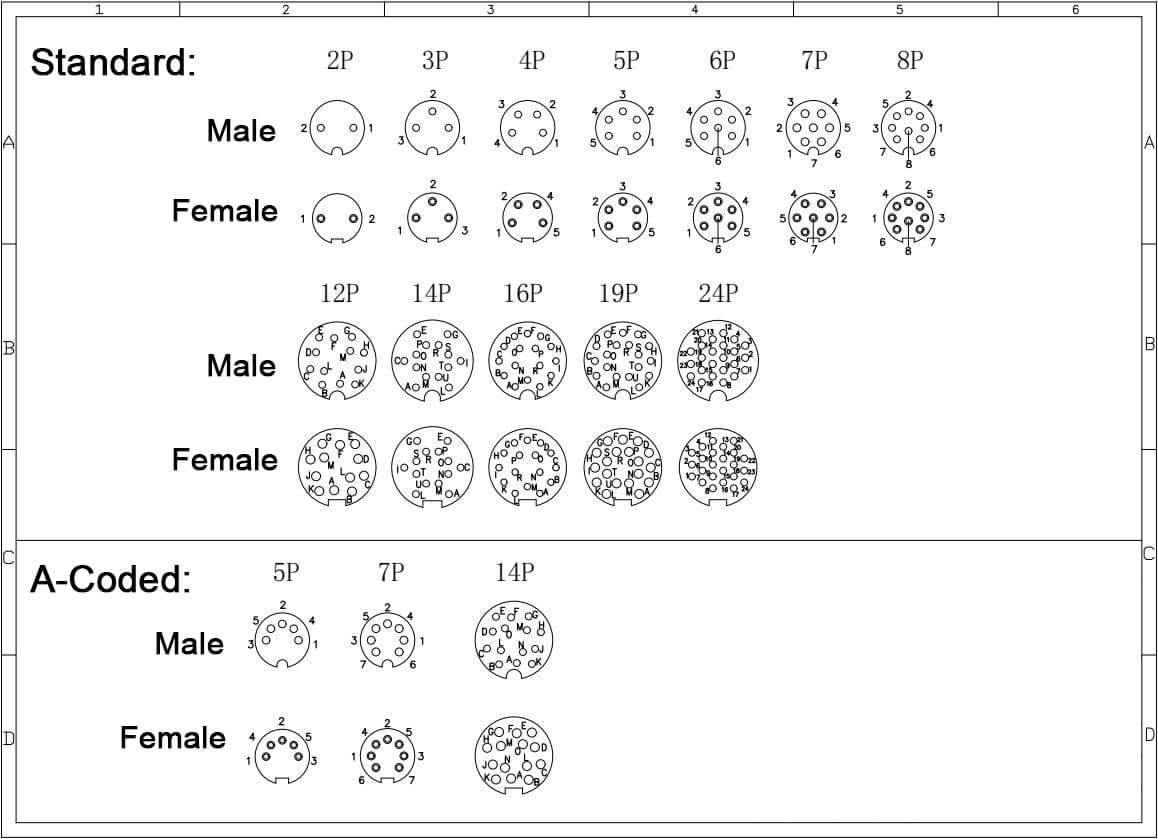

M16 connectors are circular connectors known for their versatility and durability.

They come in various coding types to handle everything from power to signal and Ethernet connections.

Their robust design and high IP ratings (such as IP67) make them ideal for harsh environments, ensuring they can withstand dust, water, and mechanical stress.

One memory that stands out is when we installed an automation system in a food processing plant.

The system operated in a wet, high-pressure cleaning environment, and choosing waterproof M16 connectors was a game-changer.

They performed flawlessly, ensuring zero downtime due to connectivity issues.

Where to Buy M16 Connectors: Top Options for Industrial Applications

m16 Connector 2 pin M16 Male Square Socket

The market for M16 connectors is vast, but finding a reliable supplier requires some groundwork.

Here’s a breakdown of the best options, along with their pros and cons.

Direct from Manufacturers

Why Choose Manufacturers?

When buying directly from manufacturers, you often get access to a complete product catalog, customization options, and guaranteed authenticity.

I’ve had great success working directly with manufacturers for large projects.

For instance, when sourcing hybrid M16 connectors (combining power and signal), the manufacturer helped us design a custom solution tailored to our machinery.

While lead times were longer, the quality and support were unmatched.

Key Manufacturers:

- Industry leaders like Binder, TE Connectivity, and Phoenix Contact specialize in M16 connectors.

Drawbacks:

- Manufacturers may have high minimum order quantities (MOQs).

- Lead times can be longer compared to distributors.

Authorized Distributors

Why Choose Distributors?

If you’re considering where to buy M16 connectors, distributors like Digi-Key, Mouser, and Allied Electronics provide high-quality, off-the-shelf options.

They often stock a wide variety of options, from M16 male and female connectors to specialized versions like D-coded connectors for Ethernet applications.

When time was tight during a factory automation project, I turned to a distributor for overnight shipping of M16 panel mount connectors.

The convenience and speed saved the day.

How to Vet a Distributor:

- Check if they are listed as authorized by the manufacturer.

- Look for reviews or testimonials from other industrial buyers.

Drawbacks:

- Slightly higher costs compared to buying directly from manufacturers.

Online Marketplaces

Why Choose Online Marketplaces?

Platforms like Alibaba and Amazon can offer competitive pricing and flexibility for small orders. However, quality assurance is a significant concern.

A colleague once purchased M16 connectors from an unknown seller on a marketplace to save costs.

While the connectors looked identical to branded ones, they failed within weeks due to subpar materials. Lesson learned: stick with verified sellers.

Tips for Using Marketplaces:

- Only buy from sellers with high ratings and verified listings.

- Avoid deals that seem too good to be true—they often are.

Local Suppliers

Why Choose Local Suppliers?

For urgent needs, local suppliers can provide immediate availability and personalized service.

Smaller distributors may also be willing to accommodate custom orders with shorter lead times.

During a power outage at one of our facilities, a local supplier delivered waterproof M16 bulkhead connectors within hours, allowing us to restore operations quickly.

Drawbacks:

- Limited selection compared to global distributors or manufacturers.

m16 Connector 2 pin M16 Male Square Socket

Tips for Evaluating Suppliers

No matter where you choose to buy M16 connectors, evaluating the supplier is crucial to avoid subpar products.

1. Check Product Quality

- Look for certifications like IEC or UL to ensure compliance with industrial standards.

- Verify materials: connectors with brass or stainless-steel housings often perform better in harsh conditions.

2. Assess Reliability

- Research the supplier’s reputation online.

- Ask for references or testimonials if dealing with a new vendor.

3. Review Customer Support

- A supplier’s willingness to provide technical guidance speaks volumes.

- Ask questions about compatibility, pin configurations, and coding to gauge their expertise.

4. Evaluate Pricing and Logistics

- Compare prices across multiple sources, but don’t prioritize cost over quality.

- Confirm shipping times and packaging—damaged goods can delay your project.

Common Mistakes to Avoid

When purchasing M16 connectors, these common pitfalls can cost time and money:

- Skipping Compatibility Checks: Ensure the connector’s coding, pin count, and specifications match your system’s requirements.

- Ignoring Certifications: Non-compliant connectors can lead to safety issues and equipment failures.

- Prioritizing Price Over Quality: Cheap connectors often have hidden costs due to shorter lifespans or poor performance.

- Overlooking Vendor Authenticity: Avoid counterfeit products by sticking to trusted sources.

Recommended Brands and Trusted Sources

Over the years, I’ve worked with many reputable brands and suppliers. Here are my top recommendations:

Brands:

- Binder: Known for durable and versatile M16 connectors.

- Phoenix Contact: Excellent for automation and Ethernet-specific applications.

- TE Connectivity: Offers high-performance options for harsh environments.

Trusted Suppliers:

- Digi-Key and Mouser Electronics: Reliable for quick deliveries and technical support.

- Allied Electronics: Great for bulk orders and custom solutions.

- Farnell: Excellent selection for European buyers.

Why Buying the Right M16 Connectors Matters for Your Business

Choosing where to buy M16 connectors isn’t just about finding a good deal—it’s about securing the reliability and performance your industrial operations demand. High-quality M16 connectors ensure:

- Minimized Downtime: Durable and reliable connectors reduce the risk of system failures and costly interruptions.

- Enhanced Efficiency: Properly coded and configured connectors streamline installation and maintenance, saving time and effort.

- Long-Term Cost Savings: Investing in certified, high-grade M16 connectors eliminates frequent replacements and repairs.

- Seamless Compatibility: With a range of options like M16 panel mount connectors, bulkhead versions, and field-wireable designs, you can find the perfect match for your machinery.

When you know where to buy M16 connectors from trusted sources, you’re not just purchasing a component—you’re investing in the success and sustainability of your business operations.

Knowing where to buy M16 connectors isn’t just about finding a seller but ensuring their products meet your specific industrial needs.

Final Thoughts

Finding reliable M16 connectors for industrial use doesn’t have to be overwhelming.

By understanding your requirements, evaluating suppliers carefully, and choosing trusted sources, you can ensure your systems operate efficiently and safely.

From my experience, it’s always worth investing time in sourcing high-quality connectors—they’re the backbone of your automation systems.

Whether you need M16 panel mount connectors, bulkhead versions, or field-wireable options, start with the recommendations in this guide and make informed purchasing decisions.

Now, it’s over to you: What’s been your biggest challenge in sourcing connectors? Let me know in the comments or reach out for further advice!

M16 Connectors Related Blog

Affordable M16 Female Connectors: Get Durable and Reliable Options

Why M16 Connectors Are the Best Choice for Automation Systems

Find High-Quality M16 A-Coded Connectors for Your Next Project

The Ultimate Guide to Buying Waterproof M16 Connectors Online

The Ultimate Guide to Buying Waterproof M16 Connectors Online

M16 Panel Mount Connectors: The Perfect Solution for Secure Connections

Where to Buy M16 Connectors: Reliable Solutions for Industrial Use Today